Gorilla Danmark

Gorilla Weld

Gorilla Weld

Couldn't load pickup availability

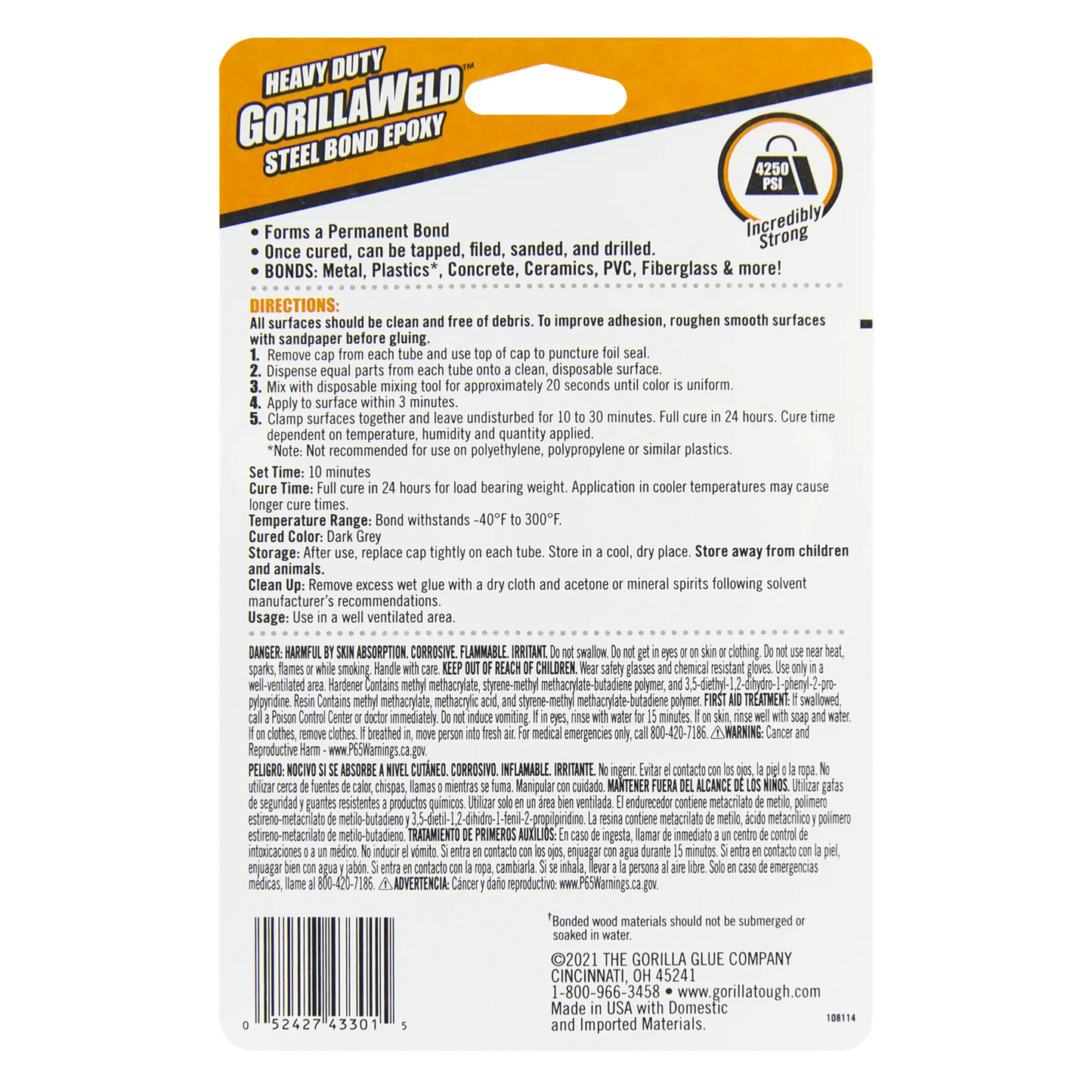

Gorilla Weld is an incredibly strong two component glue and repair compound. The tough steel bonding epoxy formula has a strength of 4250 PSI and cures in just 10 minutes.

Gorilla Weld is waterproof, versatile and creates a permanent bond to: metal, plastic, concrete, ceramics, PVC, fiberglass and much more. Can be sharpened with an angle grinder like metal.

Share

Collapsible content

Instructions

All surfaces must be clean and dry. To improve adhesion on smooth surfaces, we recommend sanding them before gluing.

- Remove the cap from each tube and use the top of the cap to puncture the foil seal.

- Apply equal portions from each tube to a clean, dry disposable surface.

- Mix with disposable mixing tool for approx. 20 seconds until the color is uniform.

- Apply the mixture to the surface within 3 minutes.

- Squeeze the surfaces together and leave undisturbed for 10 to 30 minutes. Fully cured in 24 hours. Curing time depending on temperature, humidity and quantity used.

* Note: Not recommended for use on polyethylene (PE) or polypropylene (PP) plastics.

- Sentence time: 10 minutes.

- Curing time: Fully cured in 24 hours. Application at low temperatures may result in longer curing time.

- Temperature range: Cured withstands -40ºC to 150ºC.

- Cured colour: Dark grey

- Storage: After use, screw the cap on the tube. Black cap on the Hardener tube. White cap on the Resin tube. Store in a cool and dry place. Keep out of reach of children.

- Cleanup: Remove excess Gorilla Weld immediately with a dry cloth and acetone, rubbing alcohol, or isopropyl alcohol.

- Application: Use in a well-ventilated area

Product Features

- INCREDIBLY STRONG: 4250 PSI

- STEEL BONDING EPOXY

- HARDENS IN 10 MINUTES

- WATERPROOF**

- FORM PERMANENT CONNECTION

- HARDES TO DARK GRAY COLOR

- EASY TO USE

- BINDS: Metal, Plastic*, Concrete, PVC, Fiberglass, Ceramics and more!

*Not recommended for use on polyethylene or polypropylene plastic.

**wood material that has been repaired or bonded with Gorilla WELD should not be immersed or soaked in water as Gorilla WELD does not expand with the wood. Gorilla WELD behaves like steel.

Technical specifications

- USE TEMPERATURE: 0°C to 32°C

- SERVICE TEMPERATURE: -40°C to 149°C

- SET TIME: 10 minutes

- CURING MECHANISM: 2-part reaction, requires mixing

- OUTDOOR: Yes

- FREEZE/THAW STABLE: Yes

- WATERPROOF: Yes*

- PAINTABLE: Yes

- GRINDABLE: Yes

- CAN BE DRILLED: Yes

- CAN BE SHAPED: Yes

- CAN BE COLORED: No

- CHEMICAL RESISTANCE: Limited

- EXPANDS WHEN CURED: No

- SHRINKS WHEN CURED: No

- CURED COLOR: Dark grey

- GAP FILLING: Yes

*Not recommended for use on wooden materials submerged or

soaked in water

FAQ

Will Gorilla Weld bond plastic/vinyl/rubber?

Gorilla Weld will work well on many types of plastic; however, we do not recommend use on polypropylene (PP), polyethylene (PE) or similar plastics, or any type of rubber with a high oil or plasticizer content.

What does Gorilla Weld work best for?

Gorilla Weld is ideal for metal and plastic (see above) substrates. Gorilla Weld does not sink, so it is ideal for vertical surfaces.

How should Gorilla Weld be stored?

Gorilla Weld should be stored in a cool, dry place. Keep away from children and animals.

How do I mix Gorilla Weld?

Gorilla Weld must be mixed 1:1 for 20 seconds or until uniform before application.

Does Gorilla Weld get hot during curing?

Yes, mixing hardener and resin together creates an exothermic reaction and will generate heat during curing. Consideration must be given to the mixing container so as not to melt.

How long do I have before Gorilla Weld starts to harden?

Gorilla Weld will begin to harden after 3 minutes. Adhesive must be applied before.

What surfaces will Gorilla Weld bond to?

Gorilla Weld is particularly suitable for metal, plastic and other rigid surface bonding.

Is Gorilla Weld Food safe?

Gorilla Weld is not recommended for direct or indirect food contact and should not be considered food safe.

Why is the Gorilla Weld smell so strong?

Gorilla Weld is based on methyl methacrylate chemistry, which has a naturally strong odor. We recommend use in a well-ventilated area.

How do I remove Gorilla Weld from body/skin?

Uncured: Gorilla Weld can be harmful through skin absorption and it is strongly recommended that you wear gloves during use. If Gorilla Weld is on the skin, try to remove with a dry cloth or paper towel and then wash the area thoroughly with soap and water.

Cured: Cured material can be rolled off the skin. Remove as much hardened material as possible and wash the area thoroughly with soap and water.

How do I remove Gorilla Weld from my surface?

Uncured: Wipe up as much material as possible with a dry cloth and clean up any remaining product/residue with Isopropyl Alcohol (IPA) or acetone following the solvent manufacturer's instructions.

Hardened: For removal of hardened/dried Gorilla Weld, mechanical means such as grinding or chiseling.